Valuable information about our software solutions, in bite-sized pieces.

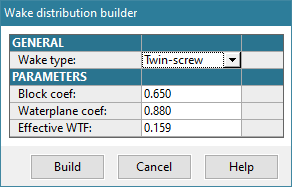

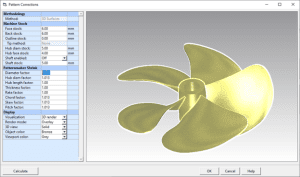

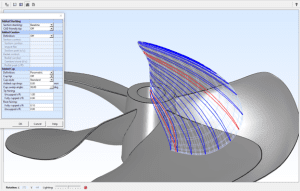

Once we develop the principal characteristics for a system’s appropriate propeller – the blade count, diameter, pitch, blade area, shaft RPM (which can be determined using NavCad) – then we can evaluate a propeller design that will be customized for the particular characteristics of the propeller environment. This is a “wake-adapted propeller design”, which is the role of PropElements. It helps refine the design of the blade to suit the inflow, leading to optimized radial distributions of key shape parameters (e.g., pitch, camber, chord length, thickness) for considerations of loading, efficiency, cavitation, and blade strength. The respective “circumferentially averaged velocities” of the propeller’s inflow can be entered or quickly estimated for axisymmetric UV bodies, single-screw ships, or shaft-driven twin-screw craft.

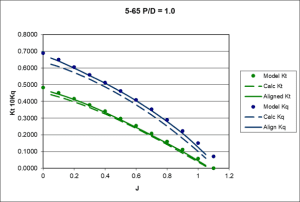

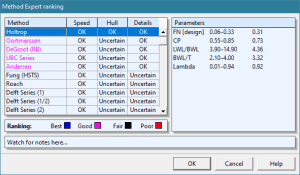

We often get questions regarding using a model test as a reference for a design variant, and that is one of the unique strengths of NavCad – and the feature that has made NavCad so popular with the tanks themselves. NavCad can leverage the value in existing model tests through the use of its proprietary “aligned prediction” technique for both bare-hull resistance and propeller performance.

NavCad’s aligned prediction is particularly valuable if the user has existing model test assets on file and is

- conducting a study on a similar vessel or propeller type; or

- evaluating a new loading condition for the same vessel.

In these cases, NavCad will deliver prediction results comparable to a new set of model testing at a fraction of the cost of a new study.

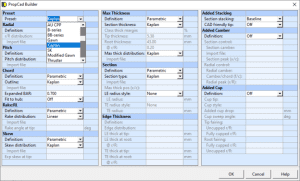

PropCad’s BUILDER includes preset options for many popular propeller design series, allowing you to design standard propellers from basic parameters like diameter, pitch, and blade area ratio.

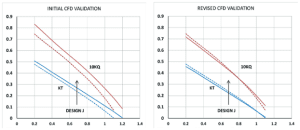

Monitoring propeller cavitation is critical, with Cavitation Inception Speed (CIS) serving as a key design metric. Tip Vortex Cavitation (TVC), often the first cavitation to appear and thus used as the CIS indicator, signals potential risk, but excessive blade sheet cavitation remains the primary cause of thrust breakdown, efficiency loss, and noise. Extending CIS through “tip unloading” may reduce TVC, but it can amplify midsection cavitation and require more power for the same thrust. Tools like PropElements® allow designers to analyze blade circulation, evaluate adjustments, and mitigate cavitation risks.

NavCad Premium’s ADVM tool gives naval architects a unique way to visualize the results of hull form modifications. The graphic shows the wave-making energy distributed along a vessel’s length. We can see that with the addition of fairing near the stern, the peak of the longitudinal energy curve is reduced.

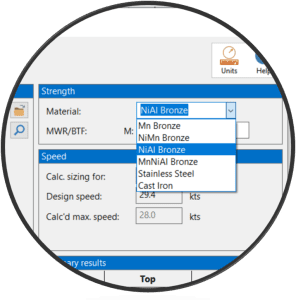

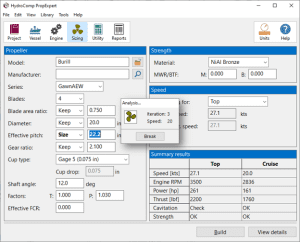

NiBrAl or Maganese bronze? PropExpert also includes a basic analysis of propeller strength based on your thrust requirements, typical blade thickness, and your selected propeller material. This helps determine if a Maganese bronze propeller, NiAlBr propeller, or stainless propeller are suitable for the application.

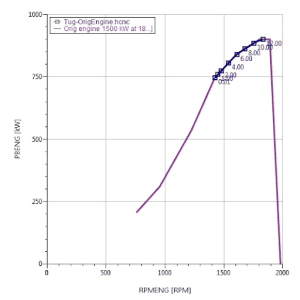

When the ship is moored (no speed), how do you calculate the propeller thrust with different RPM? How would one prepare a sample for this scenario?

It is important to understand that each entered speed will have a single associated RPM. So, I would make a project with a collection of speeds that are different, but very close to zero (e.g., 0.001, 0.002, …). In this way the speeds are effectively the same. Then set the Propulsion “Analysis type” selection to Defined. Enter the range of RPMs into the now enabled RPM column, and calculate. One note: if the objective is to use this to find the RPM that delivers the maximum thrust within the engine limits, this solution can be explicitly conducted using the Towing option (rather than Defined).

PropExpert is more than just a pitch calculator! When PropExpert sizes propellers, it is balancing thrust, power, cavitation, and tip speeds to ensure an efficient and well-matched propeller.

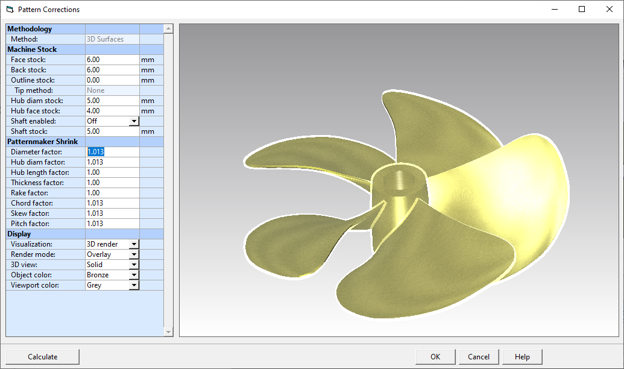

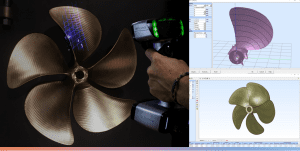

PropCad generates 3D propeller models very quickly and provides a great environment to edit the design. There are also tools for adding shrinkage and grindstock for castings and molds.

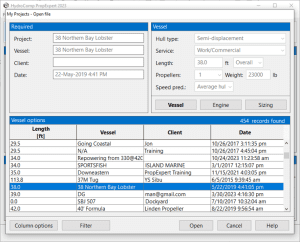

Repeat customers? Did you know that PropExpert includes a project library that manages all of your propeller sizings, clients, and job data? It’s true! Save time by having your previous sizings in an easy to use, searchable project library.

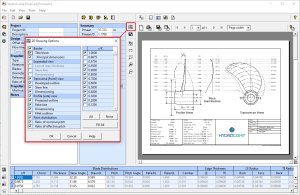

PropCad allows you to customize 2D propeller drawings from your 3D designs.

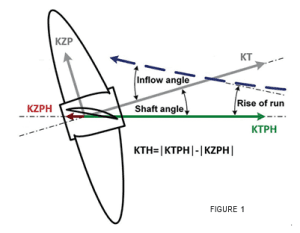

NavCad can be used to generate KT/KQ curves for actuator disks which account for oblique flow and can increase the fidelity of a CFD simulation without increased computational cost. More accurate thrust and torque figures lead to more accurate predictions of vessel speed and trim. Count on NavCad for accurate results

Adding cup to an existing propeller design is easy with PropCad’s parametric design tools. The added cup group enables easy control of cup style, height, and distribution from root to tip.

Establishing benchmarks for vessel and propulsor performance can help ensure that costly CFD runs aren’t going awry. If results are not in line with the expected values, we can halt the calculation and troubleshoot the simulation before it’s too late.

PropCad can help you recreate a propeller design from a 3D scan of a single blade. It also is great for extracting the design data from a propeller (similar to reverse engineering). Once the data is in PropCad, it can easily be altered.

NavCad’s “Method Expert” utility includes a data check to help determine if a hull may be too heavy to plane.

Both PropElements and NavCad (Premium Edition) also have a scripting API and the ability to act as a calculation server for optimization scenarios with executive tools such as Excel, Matlab, Simulink, or your own codes, for example. This is valid for any vehicle optimization.

PropElements is a wake-adapted component propeller design/analysis tool. It has special UV-relevant features for estimating radial inflow for axisymmetric bodies, as well as calculation settings for low blade area propellers.