*This article was originally published in the August 2023 issue of Maritime Reporter, written by Greg Trauthwein.

Don MacPherson, HydroComp’s long-tenured Technical Director, discusses the impacts of tightening emissions regulations, with insights on maximizing new vessel designs and refits.

Don, maritime has been in the crosshairs of regulators to reduce emissions. What do you see as the top new regulatory issues that are impacting ship and boat design, and owners, today?

What I’m seeing may be a bit of a contrarian stance and perspective. We’ve had an opportunity as a solution provider for many years to participate in a number of regulatory working groups for emissions in a broader sense. Both the greenhouse gas emission side, but also in the emerging aspects of underwater radiated noise. And I’ve seen some things that make me question objectives and motivations, not that the people involved are not well intended, certainly they’re intelligent.

What, exactly do you mean?

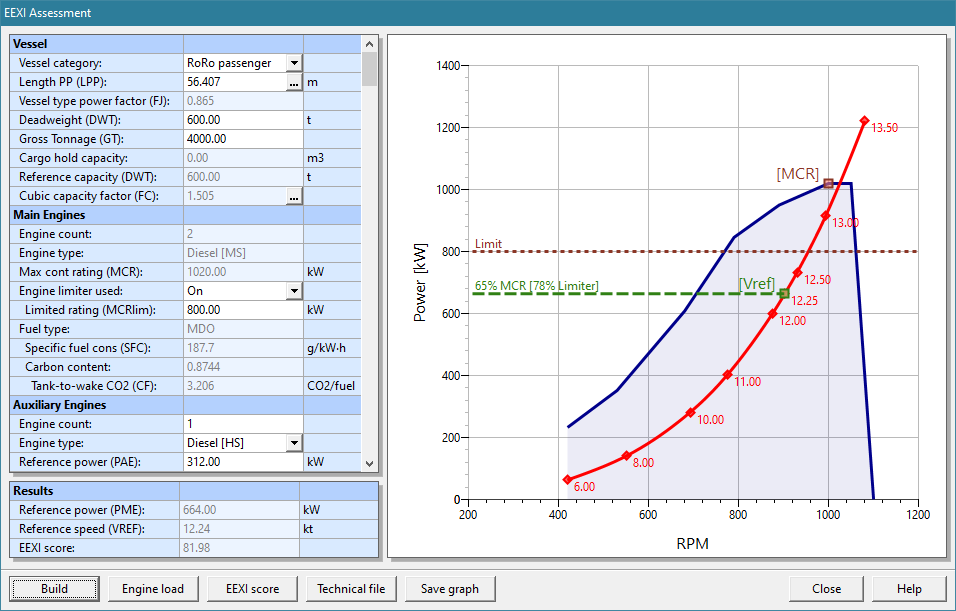

There seems to be a tendency to focus on a methodology; I would use the term orthodoxy in some cases, but that might not be fair in this particular instance. They’re focusing on how to do compliance, rather than trying to achieve broad compliance with simpler methods; for example, the EEXI calculations that are prevalent right now. Those are a pretty tightly controlled set of calculations through the various class agencies, prescribing a calculation approach using specific types of CFD calculation. The people providing the calculations have to show a competency through experience and validation calculations; that is technically valid, I understand the objectives of that. They want to make sure that everything is appropriate and in a comparative way across the board; but it’s unnecessarily complicated.

The lower limit of the bandwidth of companies that are going to have to consider this [are for vessels] as small as 400 gross tons, and that’s not a very big ship. We have one company we work with, a big international bulk carrier company, with four ships that are exactly the same: same hull; same propulsion plants; same missions. They have one set of calculations to do for that particular ship group. But a small company running one ship has to do exactly the same level of effort, and it’s an onerous task.

There are, in my opinion, simpler methodologies using reduced order methods that achieve the same end. They’re grounded in empirical testing and they fulfill the same objectives.

For years, I’ve personally questioned the merits and the appropriateness of class societies developing the regulations themselves, and also providing services to fulfill those regulations.

I know there are firewalls between the different groups and it’s not a big problem, but the unnecessary complicatedness of the EEXI calculations speaks to maybe there’s a simpler way to achieve that. And if what you’re after is broad compliance, you want to make things as easy as possible.

At the outset you mentioned underwater noise. What’s Hydrocomp’s involvement in that area?

We’ve been working with a couple international groups on formally developing compliance regulations for underwater radiated noise. There are people on the regulatory side, people in the biological sciences side, and then there are engineers and naval architects like myself. For whatever reason, this group is hung up on empirical testing as the way to fulfill compliance, as opposed to what I would term rules-based compliance.

I understand how they get there, because noise has always been tested, but interior noise testing for human response is very different than broad propagating radiated noise of a variety of different biological receptors. All the different marine mammals and sea life that are going to be affected by a ship’s radiated noise. It’s not the same thing.

You can take a pelican case with equipment and you can bring it to any ship and do interior testing functionally. Completely appropriate to do that as a test-base system.

The reverse is true for underwater radiated noise, where you have remote test facilities, which are expensive and are not common. Each facility is unique, so how do you calibrate everything to have a fair playing field. There’s a whole host of reasons why this has greater uncertainty in the test. Because you have computations for correcting reception, which is what you actually record with the transducers back to a common source level. So what you’re looking for are sound pressure levels at the source. Because that’s the only common place that you can establish a benchmark that you can then establish a compliance regulation against.

My thinking is that a rules-based approach – similar to how classification societies use rules for a propeller blade strength, or structural properties of a ship, or even damage stability calculations; we don’t test a ship to damage in order to determine whether it’s going to be safe or not. We use a rules- or a calculations-based approach, and I would propose for underwater radiated noise that is going to be the way to achieve the greatest compliance.

They say that 80% of the cost of a ship is determined in the first five to 10% of the work. Which makes sense because you lock in so many things about whole geometry, propulsion options, at the outset. All of the characteristics of a ship are locked in during that initial design, and if we can include underwater radiated noise, greenhouse gas emissions and those sorts of things early in the design process, we are going to achieve broader international compliance than we could with testing. It’s going to be faster, it’s going to be cheaper, and ultimately, it’s going to be more fair, collectively.

With some of the testing that is being proposed, what they’re saying is that we’re not going to bring everybody down to a noise level. What we’re going to initially propose is that all ships get quieter by a certain decibel, a certain sound pressure level. That’s totally unfair because you have companies that are already well entrenched in a culture of sustainability, with an interest in creating quiet ships. And so now you’re going to ask them to get even quieter, which is much more difficult to do. It’s really easy to make a noisy ship quiet. It’s not easy to make a quiet ship quieter without really extensive energy saving devices or flow manipulation devices.

So how is HydroComp a part of that emission reduction discussion?

Principally through our NavCad software tool, [with users] from small surface vessels, UV companies to the largest merchant shipbuilders, designers, operators. With NavCad you have a variety of different abilities to answer those ‘what if’ questions as a part of this hydrodynamic and propulsion system simulation.

We view everything here at HydroComp as a system problem first, and the system is a vessel propulsor drive system where you have interrelated aspects of performance between the vessel and the propulsor. This could be a propeller or water jet surface drive or cycloidal drive. Then you have relationships up the drive line from the propulsor to the prime mover, which could be a diesel engine, a gasoline engine, electric motor of a variety of different types.

And then you have to provide an energy source, an energy source that might be liquid in terms of a fuel that has a certain heating value and densities associated with it. Or it might be an electric motor amperage demand where you’re looking at trying to establish a battery budget or what you have to do in order to provide for recharging at different locations if it’s a ferry. What NavCad can provide is the ability to look at different ‘what if’ scenarios early in the design stage, where you’re going to get the greatest bang for your buck in achieving the best outcomes.

Early on you may have opportunities where slight changes in whole geometry can achieve significant savings in resistance, savings that extend through thrust demand and up the power train into fuel consumption and GHG emissions. And NavCad takes you all the way through to that GHG production predictions and estimates of what you’re going to be able to see.

That can then lead to very interesting discussions early on because it’s a good way to communicate to stakeholders, and you don’t have to have a special PhD or advanced degree to run those calculations.

I understand the philosophy of making those critical design decisions early in the process, because as the design and construction progress, it gets exponentially more expensive to change. How common is it for ship owners and builders to embrace that notion?

Great question and a tough one to answer because you can never be in a customer’s head and really understand their motivation. But a couple truths have become clear over the years. One, if it’s not regulated, it’s an option. If it’s an option, there has to be some personal or corporate motivation to fulfill that.

I’m not a big believer in altruism. People do things altruistically to feel good, and a lot of people feel good by investing in the future. My parents were both public school teachers, and they are wired that way. Certain companies are going to be wired that way; doing things because they view it as the right thing to do as opposed to it’s the most profitable thing to do. Now, to be fair, sometimes the right thing to do also is the profitable thing to do.

But when you talk about really looking downstream, that’s very difficult.

What specifically does HydroComp offer to help owners design and run their vessels with reduced emission reductions?

The biggest thing is in how NavCad, either as a purchased product or as a consulting and engineering service from HydroComp, can answer those early technical aspects of business questions. That’s the biggest thing. Now, it can also be used for retrofit evaluations, which is something is interesting with EEXI is coming up. You can create a sea trial study and then you can begin to look at [different design elements] like engine limiters, propeller options, adding a bulbous bow.

As we get onto component optimization, we have our prop elements tool for optimized propeller design, PropCad, which is what our manufacturers would use for the design and construction of propellers. And then a sister-company that Jill Aarons launched a few years back with Adam Kaplan, our propeller tools specialist in the house, is an inspection tool called TruProp. That can really help for smaller propeller, the motor yacht work community to really begin to dial in higher classes of propeller tolerance, which can lead to a little emissions improvement too. And everything you can do to make a propeller more precise will help with underwater radiated noise.

What kind of results for mission reductions can a typical client expect with the solutions that you propose?

That’s another tough question to answer because so much of that relies on the culture of the people driving the ships. A number of years ago, we were involved in the development of the software side of what’s functionally a cruise control for ships. It was a U.S. Coast Guard R&D Center project, and we found on their medium endurance cutters we could save 18% by allowing the system to drive the ship with a target speed; which was ridiculous. First of all, I didn’t believe it. I had to do a separate engineering study to prove to myself that that was even possible. And it was.

It’s easy to find big gains if your ship is very poor to begin with, or if the operational culture is, “I’ve got three days to get there, but I want to go spend a couple days in port, so I’m going to run fast in order to do it.”

If your priority is to save fuel, it starts with the culture of the operation.

But to answer your questions, I use a metric of 5%. Almost anything in hydrodynamics is limited to about a 5% improvement. And like I said (in discussing underwater radiated noise) the better you are, the less improvement you’re going to be able to see.

But it all starts with the culture. Maintenance is culture. Operation is culture. Making the system function in the best way it can, is culture. Giving you the best components of that system; that’s design.

Download this interview here.