*This article was originally published in The Naval Architect.

Little needs to be said regarding the impact that EEXI (the Energy Efficient Existing Ship Index) will have on industry. While it is somewhat controversial in many circles, the regulations are in force. The immediate challenge is how you comply.

Most discussion about EEXI relates to large ocean-going ships, run by large companies with substantial resources. However, the EEXI requirements affect ships as small as 400 gross tons, and the process to obtain compliance certification can be intimidating and costly for companies running these vessels. This is particularly true during the design-state assessment of EEXI compliance, where the objective is not to prepare the ‘Technical File’ for submittal but to investigate the current EEXI compliance status of a ship. This business planning stage can require multiple computations to evaluate the various options necessary to achieve compliance.

Compliance simply compares an EEXI ‘score’ to a ship-type criteria, so why are EEXI compliance calculations so difficult and costly? The reason is principally to ensure appropriate commonality for each submittal, so that no one can ‘game’ the calculation of the score. This requires the prediction of an approved speed-power curve from which is extracted a reference speed, power, and fuel rate. This has led to a set of requirements that are intricate, require a narrow definition of acceptable methodology, and can only be accepted from approved and verified providers (the class societies themselves being among them).

For example, computations using the defined methodologies would require:

- Numerical computations. These are narrowly prescribed as CFD calculations that implement “Reynolds-Averaged Navier-Stokes equations as governing equations with the considerations of viscosity and in presence of free surface” [IACS Recommendations 2022, No. 173]. To utilise CFD, however, practitioners are required to demonstrate qualification in CFD computations and to conduct calibration/validation studies as part of the calculation of the reference speed-power curve.

- Model tests. Tank tests of resistance, self-propulsion, and/or propeller open-water performance following ITTC-1978 guidelines can be utilised in the calculations. This includes tests for ship load conditions that are different from the prescribed EEXI draft conditions (typically the summer load line).

- Sea trials. Trials conducted for normal business and operational planning are typically insufficient for use in the prescribed EEXI methodology. Approved trials must be conducted according to ISO or ITTC recommendations, which includes the use of specified and accepted shaft torque measurement equipment and with an independent ‘verifier’ present during testing.

Calibration of CFD computations would use the above-described model tests or sea trials of the subject vessel. The guidelines do allow for calibration using model tests of an appropriate similar ship, such as a known benchmark hull or an in-house test of another vessel design. However, approval for the use of a different ship requires documentation of the technical methods employed for calibration and it subject to the discretion of the regulatory ‘verifier’.

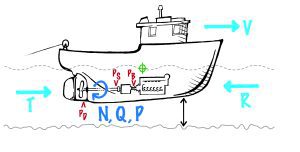

Figure 1. Illustration of NavCad’s Vessel-Propulsor-Drive system simulation model.

While the intent of these prescribed computational methods is laudable from the regulatory perspective, there needs to be a distinction made between what is needed for the strict requirements of compliance and what is useful and appropriate for the design investigations. In face, reliable – and technically valid – alternative methodologies are available. Effective resource-friendly evaluation of the EEXI score for design investigation has led HydroComp to develop its new EEXI Assessment utility for the upcoming NavCad 2023 Premium Edition.

Let us share an example of a small 70m ro-pax vessel wanting to investigate its current state of EEXI compliance, and to evaluate measures that might be taken if found to be non-compliant. General specifications of the ship are:

- Length overall: 70m

- Displacement: 240t

- Deadweight: 985t

- Propulsion power: 2 x 900kW medium-speed diesels

- Auxiliary power: 1 x 250kW diesel-generator

This is a pre-EEDI ship, so there are no prior computations to build upon. Conducting a design investigation according to the prescribed methodologies could mean multiple iterations of the detailed compliance calculations, including CFD verification and calibration to approved model tests or validated sea trials. For this example, sufficient CAD models and existing ship performance data were available to prepare a NavCad project that follows the same objective approach of calibrated models with technically appropriate methodologies, but without the overhead and resource costs of the compliance restrictions.

Built upon an equilibrium Vessel-Propulsor-Drive system simulation model, NavCad can predict the various components of the system, including bare-hull and appendage resistance, drag due to the ship’s windage area and speed, hull-propulsor interaction factors, propeller performance, and engine demand (including fuel consumption). NavCad can also utilise resistance and self-propulsion model tests directly or for correlation as a ‘reference ship’ with its ‘Aligned Prediction’ feature. Propeller open-water tests can also be used for propeller performance, or as a ‘reference propeller’ of an ‘Aligned Series’. In both cases, alignment can be tests specific to the ship being investigated, or alternatively aligned with easily obtained tests from published benchmark studies.

Data for alignment can also be developed in NavCad from sea trials that includes some measure of engine demand – either recorded engine load percentage or fuel consumption. NavCad will determine an equilibrium propeller thrust (correlated to the recorded engine load metric) and then extract the vessel resistance at the trial condition. This can then serve as the ‘reference ship’ for correlation from the trial condition to the EEXI draft condition.

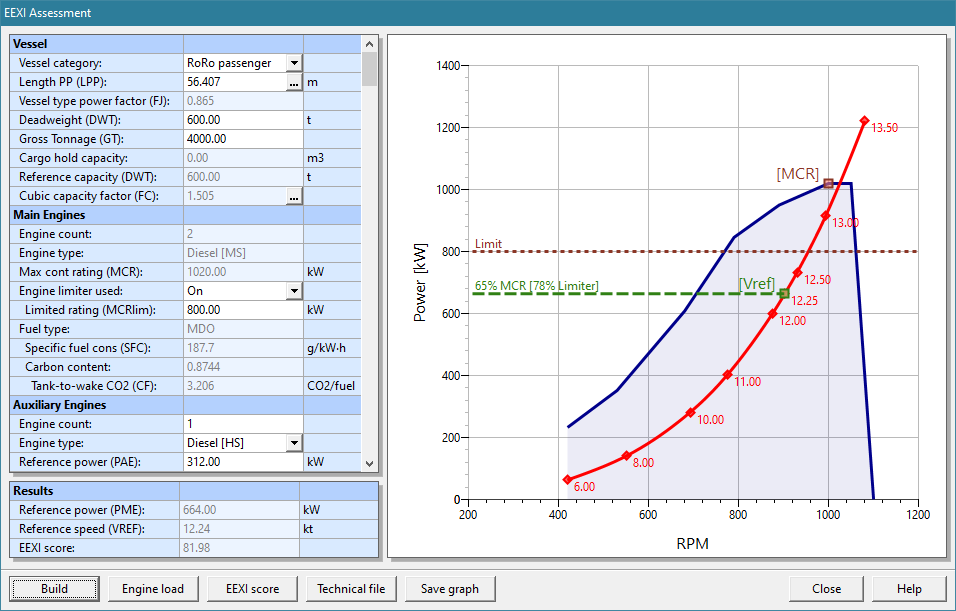

Figure 2. NavCad’s new EEXI Assessment utility.

One then has a fully calibrated simulation model to establish a suitable speed-power curve for determination of the EEXI reference power and speed. In the case of this 70m ro-pax example, a model test was found for a similar ship of comparable corresponding speed (FN), hull parameters (such as L/B, B/T, and fineness coefficients), and significant characteristics (transom immersion or bulbous bow). An ‘Aligned Prediction’ then established the basis for the bare-hull resistance component in the system. Appendage and added resistances were prepared using the available prediction models in NavCad library.

Hull-propulsor coefficients (wake-fraction, thrust deduction) were predicted using a method from its library that was highly ranked by NavCad’s ‘Method Expert’ – a utility to ensure that the prediction method conforms to the hull form, speed range, and characteristic details of the ship. Propeller performance was predicted with one of the various systematic propeller series, but with options to account not only for historical experience with the propeller model (thrust and power correlation factors), but also for explicit effects of oblique flow (from shaft angle), added camber or cup, blade thickness, and even cavitation breakdown. The specification data for the diesel engine was obtained and entered from the manufacturer’s technical sheets.

Once the system simulation model is in place and the equilibrium calibration of the speed-power curve complete, it is a simple matter to run the EEXI Assessment utility. This ship narrowly failed EEXI compliance in its existing condition, so various mitigation options could be reviewed, including engine limiters, very low sulphur fuel oil (VLSFO), propeller modifications, even hull cleaning.

In summary, the new utility calculates the EEXI score, produces plots for the speed-power curve (as shown by an engine load plot of speed, power, and RPM in the figure above), and generates an EEXI Technical File report for reference (including technical explanation of the methodologies used). This utility is easily operated by any practicing naval architect or marine engineer, is suitable for virtually all ships under EEXI restriction, generates reference documentation for future quality assurance or benchmarking of the compliance calculations, and provides quick and resource-friendly design guidance when the need comes to investigate where a ship stands regarding EEXI compliance.

The new EEXI Assessment utility will be available early 2023 as part of the Premium Edition of NavCad. For more information, please contact HydroComp, Inc. or visit www.hydrocompinc.com/eexi.