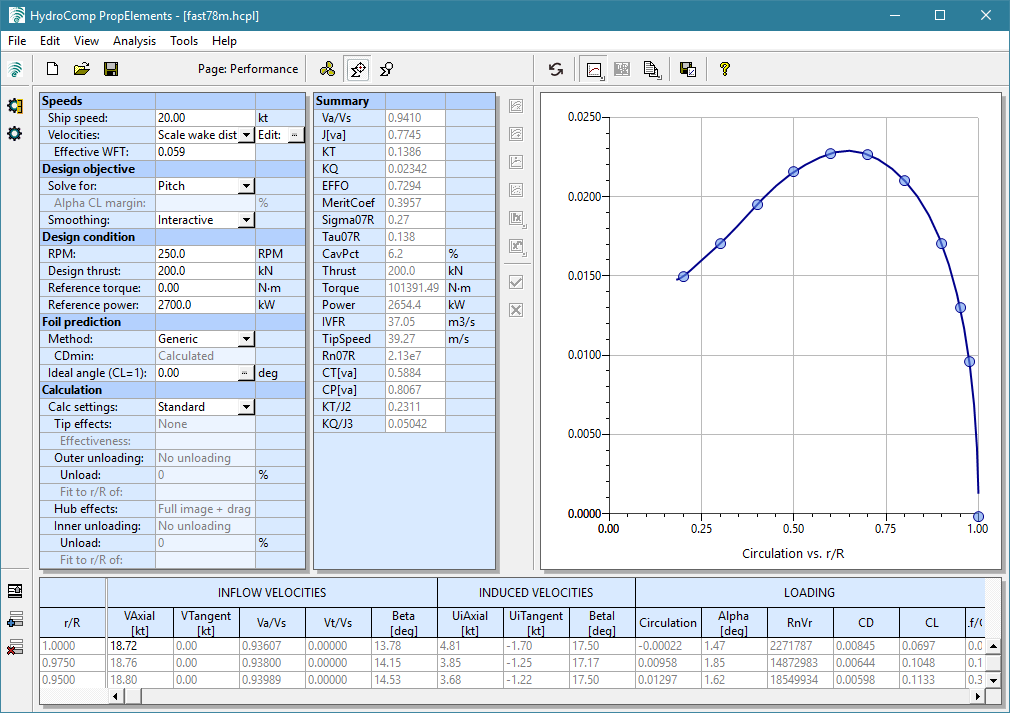

PropElements

Propeller Design for Performance

Request a Quote

Renew MSU

MSU Subscriptions

Request an Update

Optimize and Understand Your Propeller

HydroComp’s PropElements brings a specialist tool to a broader engineering community. PropElements is designed not only for propeller specialists and manufacturers, but for naval architects and vehicle designers as well.

Wake-Adapted Propeller Performance

PropElements provides an optimizing design stage between parametric specification and full 3D design for manufacture. It builds on the system specification of necessary propeller characteristics (such as those from NavCad) to the design or evaluate a propeller in greater detail to meet the ship mission objectives.

Many large, merchant ships utilize custom propellers and more smaller ships, yachts, and workboats also appreciate the benefits of a custom propeller. Naval architects now have a new set of technical challenges to ensure acceptable performance and compliance with design requirements. To fully take advantage of the benefits that custom or semi-custom propellers make available – or to evaluate them in service – naval architects must look to a different kind of propeller calculation. Extensive validation studies for PropElements confirm it is unmatched in calculation fidelity and workflow efficiency.

Used by/Industries

Propeller designers and builders

Naval architects and engineers

Hydrodynamicists and researchers

Propulsion system specialists

Classification societies

Add Propeller Calcs to Your Workflow

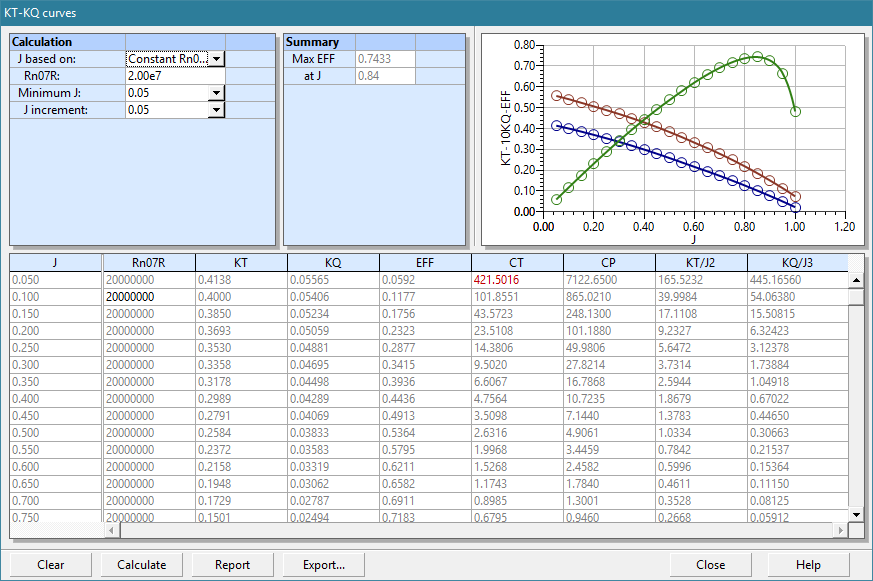

PropElements’ numerous import/export options makes it an important companion for our NavCad and PropCad software, as well as the perfect pre-processor for higher-order flow codes, CFD, and FEA. Connect the KT-KQ data to NavCad for “Aligned Series” prediction of propeller performance. Then, when the propeller design for performance has been completed with PropElements, its design for manufacture can be conducted in PropCad.

CFD-Friendly Analysis

A closely-coupled connection between a CFD code and HydroComp PropElements software offers a high-fidelity and highly-efficient alternative to an actuator disk. Using easy-to-implement capabilities for object-oriented scripting and cross-product connectivity, it is the ideal propeller performance server for integrated hull-propeller analysis with CFD.

Features

Comprehensive propeller design and analysis

Wake-adapted calculation tool for analysis or design

Support for open or ducted, hub- or rim-driven propellers

Proprietary features and calibration for quantitative accuracy

Design of optimum radial distributions

Analysis of thrust and power performance

Review of cavitation and other criteria

Blade strength using beam theory

Creation and export of KT-KQ curves

Export for CAD/CAM/CFD/FEA

Professional reports and plots

Technical Specifications

Calculation Groups

- Project

- Geometry

- Performance

- Strength

- KT-KQ

Water Types

- Fresh

- Salt

- Brackish

- Custom

Solve For

- Pitch + Camber (ideal)

- Pitch

- Thrust

Configuration

- Open FPP

- Ducted FPP

- In tunnel

Foil Definition

- Universal

- NACA 66 mod

- Bi-Circular

- Segmental

- Custom

Velocities

- Axial only

- Axial and tangential

Wake Distribution

- User entered

- From wake file

Tip and Hub Corrections

- Custom unloading

- Hub image

- Hub drag

- Rim image

Advanced Features

- Proprietary 3D corrections

- Optimum circulation

- Full wake-field prediction of induced velocities

- Scripting and use as coupled calculation server

Materials

- Mn bronze

- NiAl bronze

- St steel

- Custom

KT-KQ

- Constant speed

- Constant RPM

- Constant Rn07R

Keep propelling forward. Sign up for a HYDROCourse.

Related Video and Tutorials

Introduction to PropElements

A quick video introduction to HydroComp PropElements, a software tool for wake-adapted propeller design and performance analysis! PropElements provides an optimizing design stage between parametric specification and full 3D design for manufacture. It builds on the system specification of necessary propeller characteristics (such as those from NavCad) to the design or evaluate a propeller in greater detail to meet the ship mission objectives.