News & Events

Upcoming Events

Navalia 2024 – Vigo, Spain

May 21 - May 23Instituto Feiral de Vigo (IFEVI)

We will be proudly represented by NDAR.To make an appointment, please contact Stéphane Dardel.Mobil...

Company News

Apr

2024

15

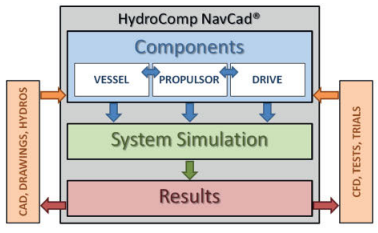

Pairing of Multi-Order Tools for Practical and Effective System Simulation

Naval architects require capabilities for effective and credible hydrodynamic and propulsion...

Mar

2024

13

Be Environmentally-Friendly with HydroComp NavCad: How THEMS Uses the Software to Promote Electromobility

Leer en español aquí. A conversation with Joel Pérez Osses and Claudio Troncoso Environmental...

Jan

2024

31

Our Neighbors to the North: Service Marine Canada Increases Client Range with HydroComp Software

A conversation with Dominique Plouffe of Service Marine Canada Service Marine Canada, located...

Jan

2024

8

2023 Recap

Another year has quickly passed and we continued to be very active and wildly productive at...